Estimating the direct material used helps a company to calculate the point of reordering (reorder level). This means more raw material needs to be bought for production at this level. Direct material is a recipe for the manufactured item as listed under the bill of materials. Next up is understanding why direct materials really matter when tracking production costs.. Indirect materials refer to materials consumed during the manufacturing process.

Cost Estimation and Forecasting

These materials form the physical essence of your creations, directly contributing to their quality and cost. Calculating direct materials used is not just a mundane task; it’s a vital step that empowers you with profound knowledge about your production process. Efficient inventory management is key to successful budgeting for raw materials. Implementing robust systems to minimize waste and losses enables organizations to optimize resource utilization.

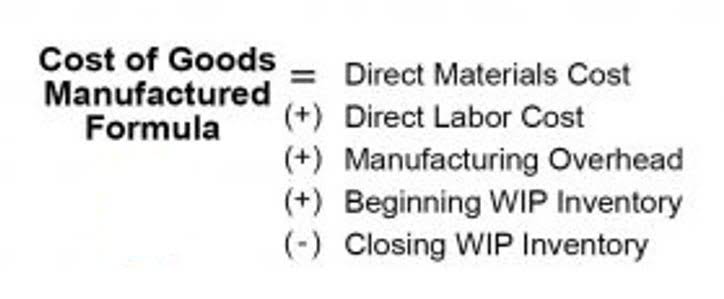

How to Calculate Cost of Materials

- Direct materials procurement involves various uncertainties that can impact both cost and availability.

- You can dual purpose the direct material used formula to calculate both the cost and quantity used in production.

- They are often the largest chunk of costs that rise and fall with production levels.

- Direct material cost fluctuates a lot from unstable purchasing conditions and unpredictable manufacturing controls.

- The cost of direct materials significantly impacts a product’s overall manufacturing cost, influencing its profitability and competitiveness.

- Look for patterns or repeated issues that cause unexpected destruction of materials.

- The quantity of direct materials used and recorded at an estimated usage rate is then converted to standard cost.

Yes, the price of these raw items can vary due to market conditions or supply issues. Direct materials don’t hide; bookkeeping and payroll services they stand out because you can easily spot and measure them in every completed item. They are the nuts and bolts that give life to your product – literally! Without them, those shiny gadgets or tasty treats wouldn’t make it past a sketch on paper. Determining the exact cost of carriage inwards can be complex, especially if materials are sourced from multiple suppliers or locations.

Application of Linearity Assumption to Calculate Direct Material Cost

For example, if the closing stock at the QuickBooks end of January is ₹20,000, this amount is deducted from the total. The beginning direct materials inventory represents the value of raw materials on hand at the start of a specific accounting period. This inventory serves as the foundation for calculating the total materials available for use during the period. Monitoring direct materials used helps maintain optimal inventory levels. Accurate usage data ensures that businesses can effectively plan future purchases, avoiding both overstocking and shortages.

- An equation for calculating the cost of production using specified values for materials and labor costs is derived.

- LIFO reduces the tax, but only a few businesses want to sell or use the newest stock before the old inventory is over.

- Accurate COGS enables better planning, budgeting, and decision-making.

- These essential inputs not only shape the manufacturing process but also significantly influence a company’s variable costs—and ultimately, its bottom line.

Direct Material Cost per Unit

Businesses must track these numbers closely for inventory management and pricing strategies. When a company finds it hard to separate direct materials stock according to the date of purchase, the weighted average method is employed. Direct material can be tracked unit by unit using specific identification. A standard costing system total manufacturing cost formula allows your company to run its operations without waiting for the actual cost order to act. The direct material used and the purchase price are estimated using the available information. After setting the budgeted cost for direct material, the company can plan for purchases and production.

Include the shipping costs your business incurred in the calculation, called freight in. Direct materials ending inventory is vital for accurate financial reporting. It helps you gauge the cost of materials still available at the end of a period. Accountants must watch direct materials closely as they move from inventory to production.